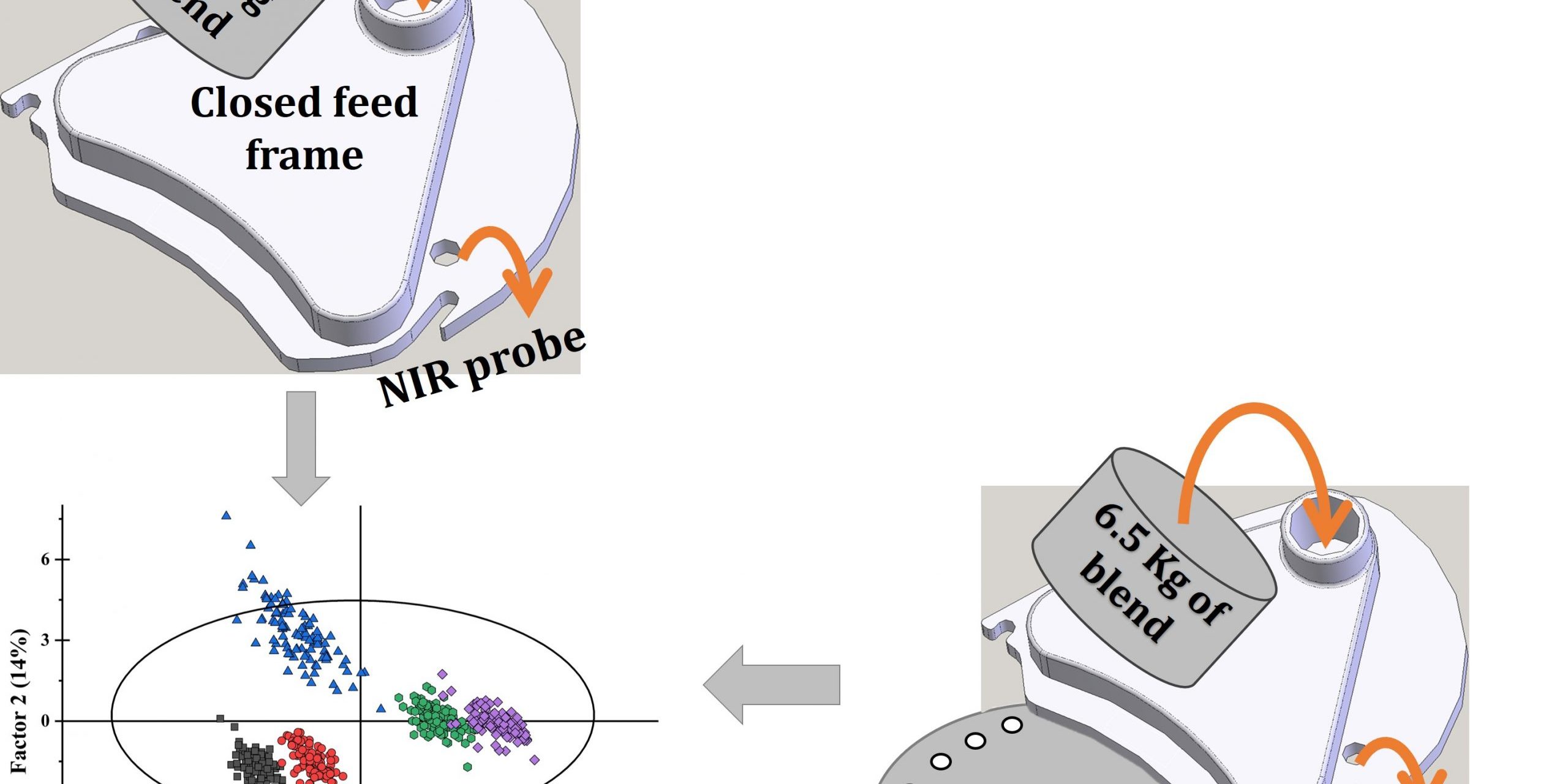

September 12th, 2023 – This paper shows two case studies where the closed feed frame (a feed frame where the die disc is not turned on) is used as a material sparing approach to develop calibration models for monitoring blend uniformity.

Movilla-Meza, N. A.; Sierra-Vega, N. O.; Alvarado-Hernández, B. B.; Méndez, R.; Romañach, R. J. The Use of a Closed Feed Frame for the Development of Near-Infrared Spectroscopic Calibration Model to Determine Drug Concentration. Pharm. Res. 2023.

Abstract

This study evaluates the use of the closed feed frame as a material sparing approach to develop near-infrared (NIR) spectroscopic calibration models for monitoring blend uniformity. The effect of shear induced by recirculation on NIR spectra was also studied. Calibration models were developed using NIR spectra obtained in the closed feed frame for two cases. For case 2, blends that flowed through the open feed frame were predicted with the model. The shear effect of the feed frame on the blends was assessed through the characterization of the powder properties before and after recirculation. The physical characterization of the blends confirmed that the powder properties were not altered after recirculation within the closed feed frame. Both calibration models provided highly accurate predictions of the test blends with low bias (0.03% w/w and -0.06% w/w) and relative standard error of prediction (1.9% and 3.7%), respectively. The predictive performance of the calibration models was not affected by the shear effect. Recirculation within the closed feed frame did not change the physical properties of the blends studied. The predictions of blends flowing through the open feed frame was possible with a calibration model developed in the closed feed frame. The closed feed frame could reduce the materials needed to develop calibration models by more than 90%.

https://link.springer.com/article/10.1007/s11095-023-03601-1