Our facilities consist of two research laboratories at the Chemistry Department building at UPR-Mayagüez. The spaces are set up for working with pharmaceutical powder mixtures and data analysis. The main laboratory consists of about 1000 square feet and is set up for working with pharmaceutical powder mixtures. This laboratory also has three additional computers with multivariate data analysis software. This second space is dedicated to data analysis. This laboratory space is equipped with 5 computers for students to use in multivariate data analysis, with Unscrambler 11 from Camo and Pirouette from Infometrix, for students to closely examine the data obtained and develop suitable chemometric models. Other programs such as Vektor Direktor, Matlab, Python, and others are available.

Spectroscopic Equipment

Matrix FT-NIR spectrometer with a Q-412 emission probe from Bruker Optics; frequently used for real time measurements of flowing powders.

Multipurpose Analyzer (MPA™) from Bruker Optics, which can obtain near infrared spectra for liquids, powder, tablets, and other materials.

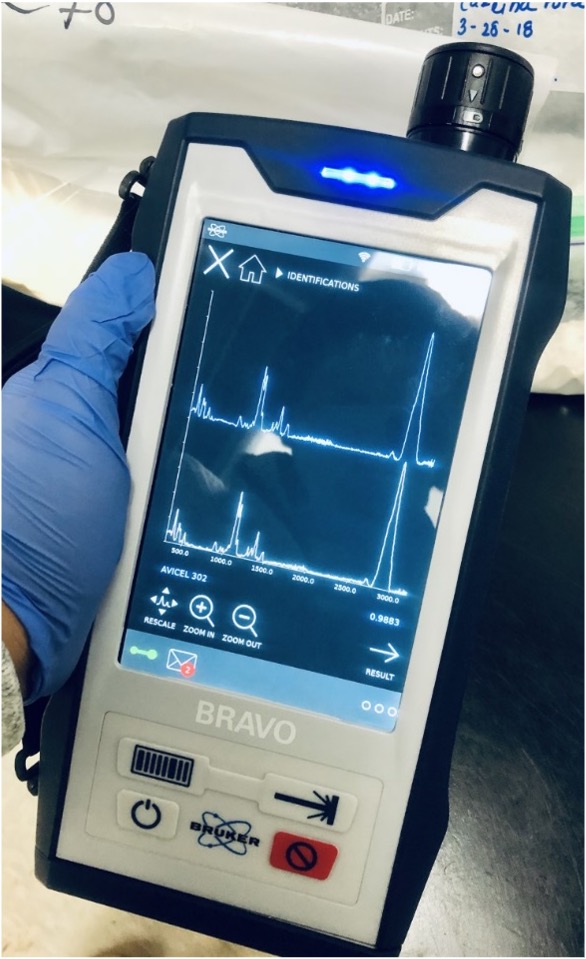

Bravo handheld Raman analyzer from Bruker Optics is currently being used in training of pharmaceutical industry in for raw material, API and cell culture media identification.

MarqMetrix All-in-one M73 Raman spectrometer equipped with a ball probe head for powder and liquid sample analysis in real time.

Viavi MicroNIR Pat-U spectrometer; used in for real time measurements of flowing powders.

Spectral Engine NIRone Models S1.7 and S2.0 Spectrometer. This small equipment are used for educational purposes.

Evolution 60S UV spectrometer from Thermo Instruments; used as reference method when determining blend concentration from sample power blends collected in real time.

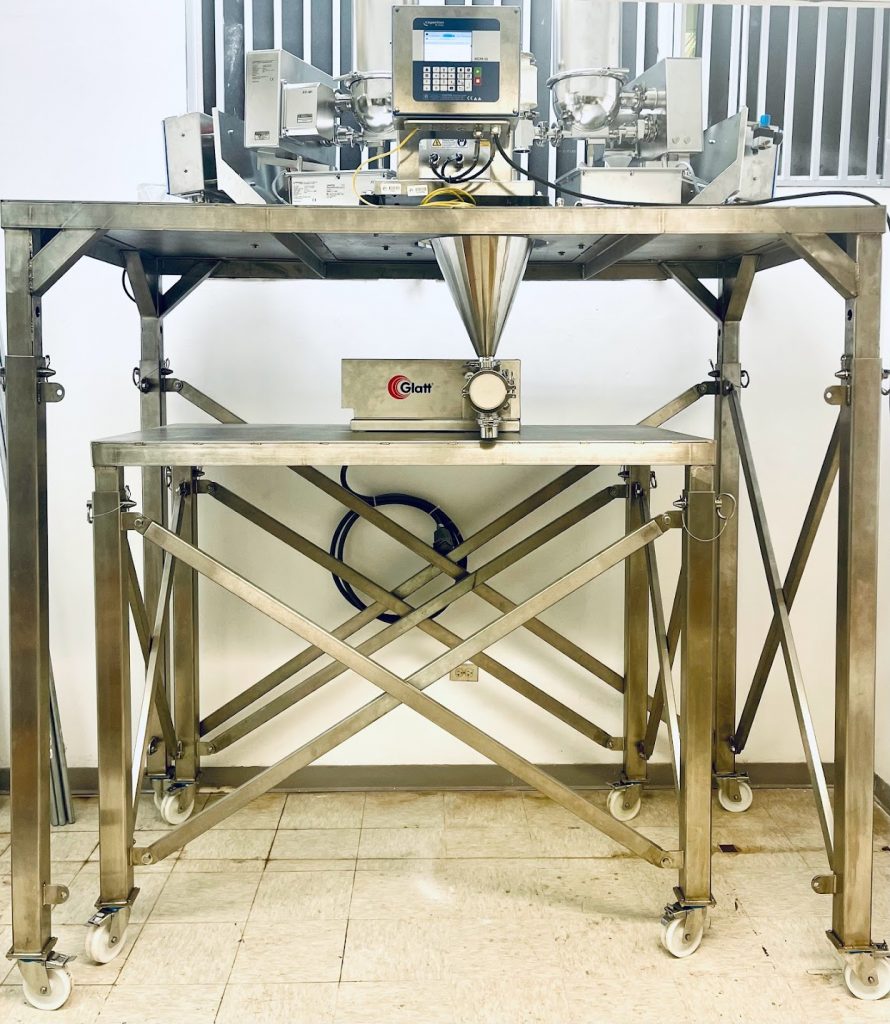

Mobile Continuous Manufacturing Line

Mobile Training Unit, this small continuous manufacturing line contains all the equipment needed for continuous blend preparation.

Front view of Mobile Training Unit in our lab. The line consist of the following:

Top level – (3) Feeders and control unit.

•Two Ktron QT-20 (Max: 18.5kg/h)

•One MT-16 (Max: 18.8kg/h)

Middle – Continuous Blender

•MODCOS Dry Mixer 70 Modular continuous system (10-30kg/h)

Continuous and Batch Manufacturing Equipment

Our facilities also have available batch and continuous manufacturing equipment used in our research activities. The equipment consists of the following:

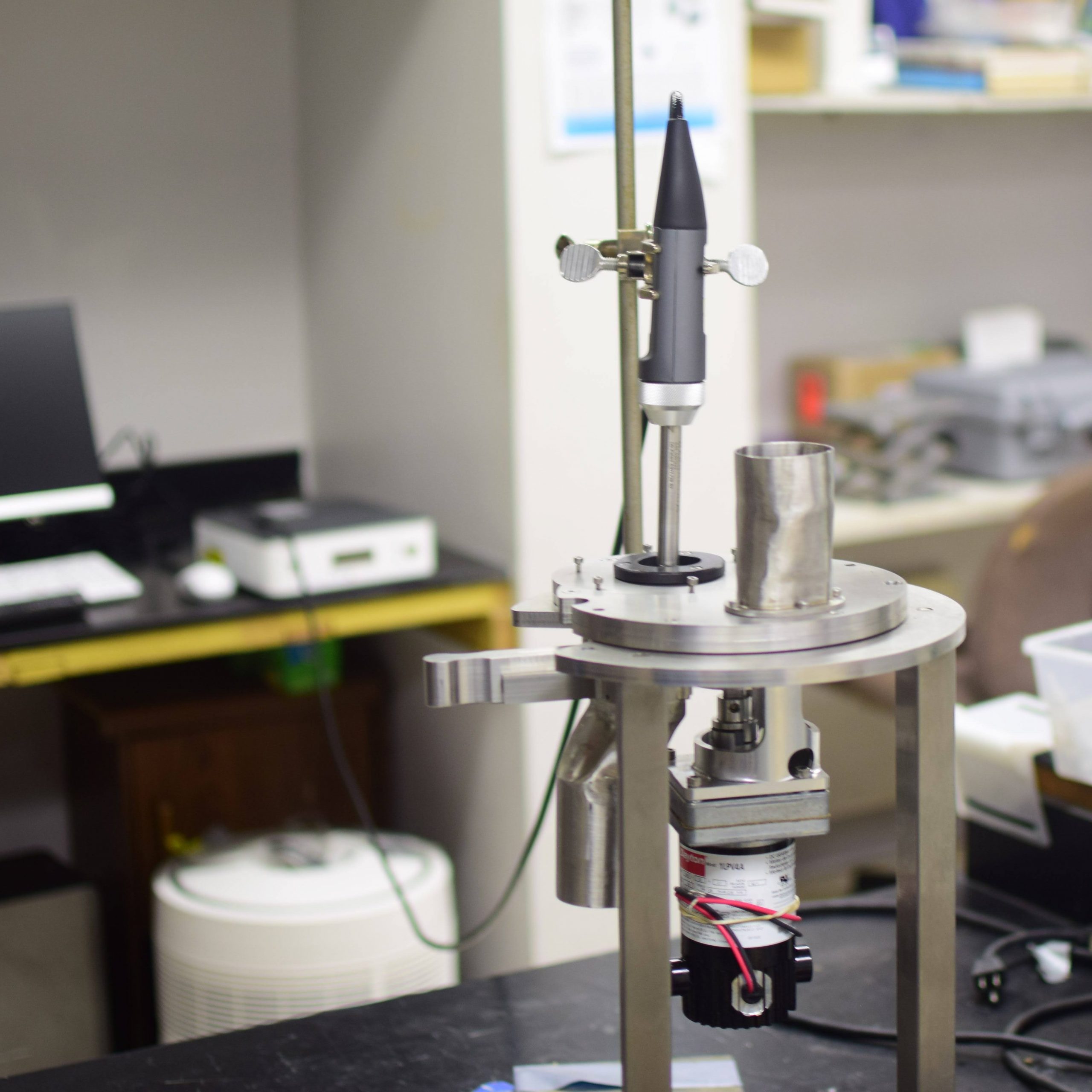

Stream Sampler system for flowing powders designed through an NSF SBIR grant (US Patent 10520400), coupled with the Mark Matrix All-in-one M73 probe.

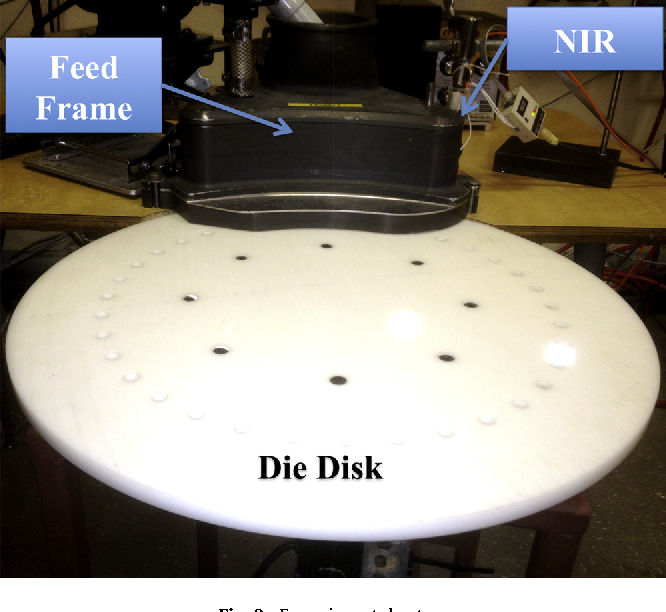

3090 Fette feed frame used in combination with equipment such as the Bruker optics Matrix-F with Q412 probe or the Viavi MicroNIR PATu.

K-tron QT-20 gravimetric feeders used in our Mobile Continuous Manufacturing Line.

K-tron MT16 feeder

Glatt MODCOS Dry Mixer 70

16qt V-blender; a 4qt v-blender is also available for smaller powder blends.

Characterization Equipment

Material characteristics are a very important aspect when determining optimal processing parameters. The laboratory is equipped for powder characterization equipment with:

FT4 Powder Rheometer from Freeman Technologies

AccuPyc 1340 Automatic Gas pycnometer with 10 cm3 sample capacity

Autotap-TM Tapped Density Analyzer

Laboratory Equipment

The laboratory includes a drying oven, planetary shaker, sonicator, tachometer and centrifuge for extractions of analytes needed for reference method analysis. The laboratory also includes two analytical balances and an 870 Karl Fischer Tritrino Plus system for determination of moisture in materials.