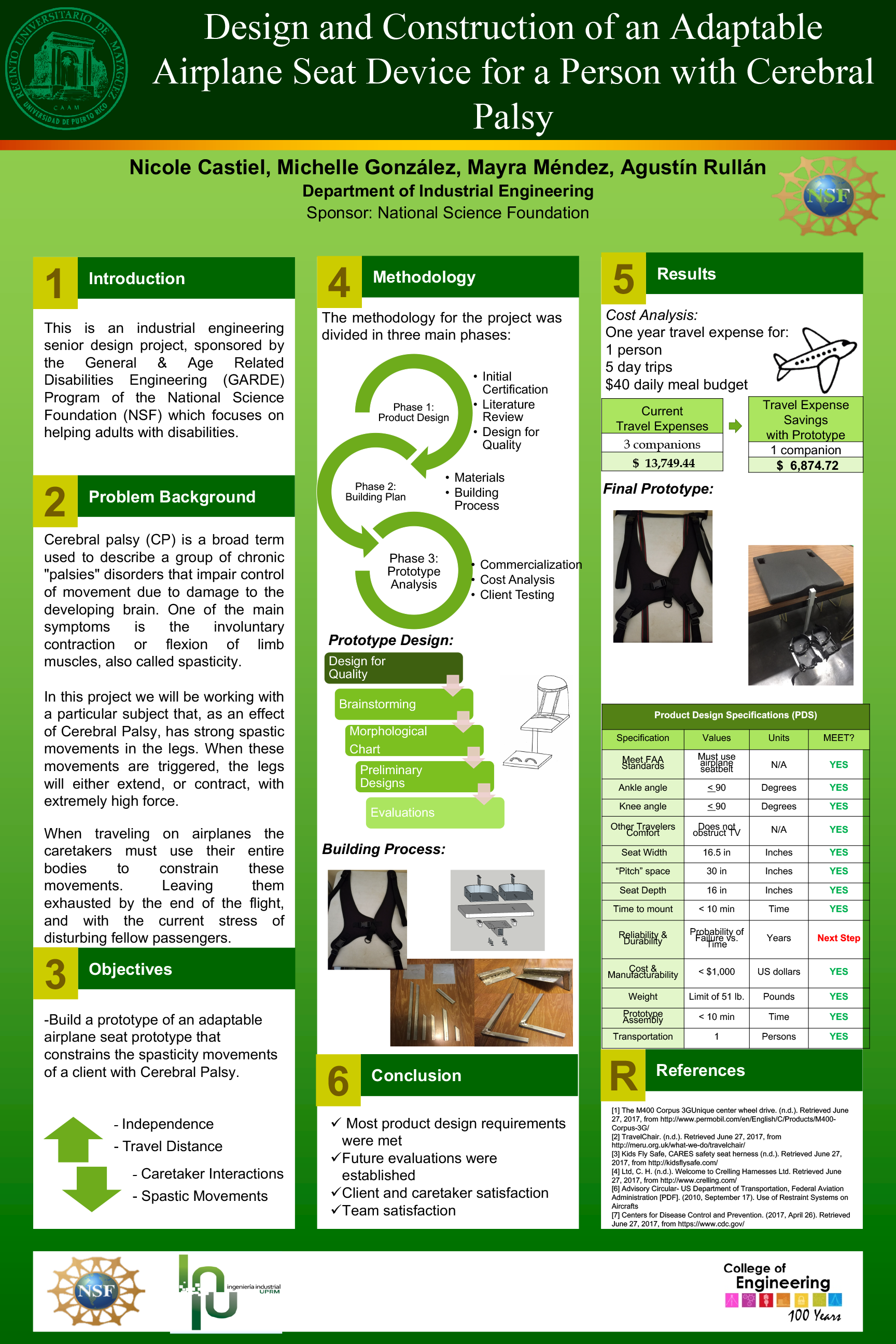

Making the Difference: Design and Construction of an Adaptable Airplane Seat Device for a Person with Cerebral Palsy

Student Team:

Michelle González, Industrial Engineering Senior Student

Nicole Castiel, Industrial Engineering Senior Student

Faculty Mentors:

Agustín Rullán, PhD

María Irizarry, PhD

Cristina Pomales, PhD

Mayra Méndez, PhD

Project Synopsis:

Making the Difference:Design and Construction of an Adaptable Airplane Seat Device for a Person with Cerebral Palsy (CP), seeks to benefit adults with disabilities. This project is focused on helping a client with cerebral palsy (CP) travel on airplanes without mayor assistance from caretakers or flight attendants. It also targets the reduction of disturbances to surrounding passengers because of the client’s spastic movements. Building a device that will constrain these movements without the assistance of another person will give the client more independence, and the ability to travel longer distances. This will also help reduce the cost of travel, lodging and transportation of the people assisting the client. To accomplish this, initial research had to be done to better understand the client’s condition, and to determine if there were any commercial products that complied with the client’s requirements. After concluding that no single product could give the client all the necessary support, four preliminary designs where developed, modified, and evaluated. With the help of the client, and subject matter experts, a final design was selected. This design offered all the necessary leg constraints and torso supports needed for the client. It was also lightweight and portable for the caretakers to carry around at the airport. Most importantly, the prototype designed complied with Federal Aviation Administration (FAA) seatbelt regulations. An initial prototype was built as proof of concept and to evaluate assembly, transportation, and mounting times. After positive results, a final prototype was built at a total cost of $466.70. This cost was analyzed from three perspectives: prototype cost, total product cost, and customer benefit. Given that this prototype was designed for a particular client, a commercialization potential analysis was carried out to determine the population it could benefit. Finally, a successful client test was done to verify that the prototype complied with all device and client requirements. This project was supported by the National Science Foundation contract CBET-1403753, “Making the Difference: An Industrial Engineering Capstone Design Experience to Benefit Adults with Disabilities.”