Making the Difference: Project Lapsus-How can we help patients sit & stand quickly and pain free?

Student Team:

Joan I. García Torres, Industrial Engineering Senior Student

Nicole Méndez Santos, Industrial Engineering Senior Student

Manuel J. Pérez Vargas, Mechanical Engineering Senior Student

Grexarie Torres Caraballo, Mechanical Engineering Senior Student

Faculty Mentors:

María Irizarry, PhD

David Serrano, PhD

Mayra Méndez, PhD

Cristina Pomales, PhD

Project Synopsis:

Making the Difference: Project LAPSUS is part of a project sponsored by the National Science Foundation (NSF) that seeks to benefit adults with disabilities.

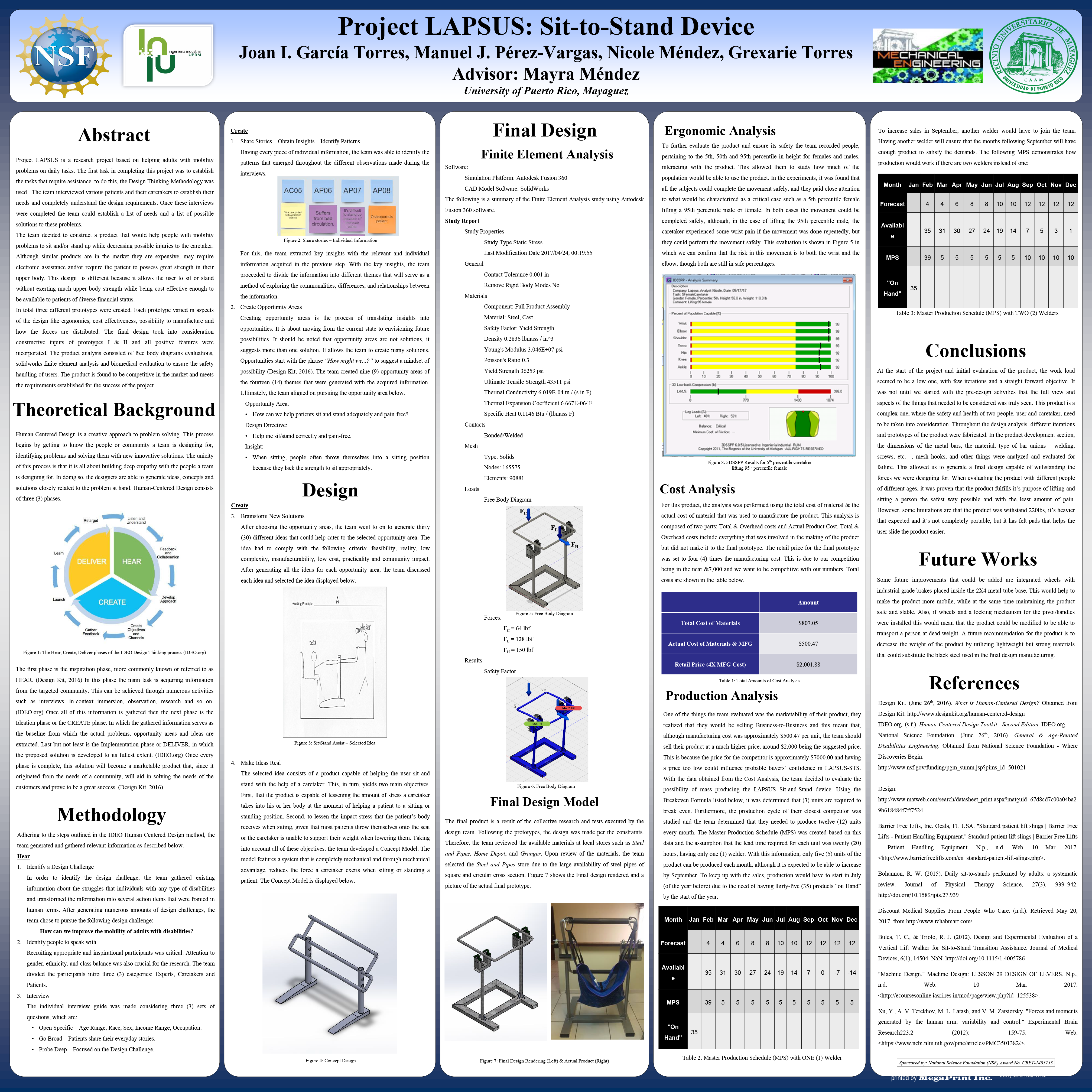

Project LAPSUS is a research project based on helping adults with mobility problems in their daily tasks. The first step in completing this project was to establish the tasks in which, these adults require assistance. This was achieved through the Design Thinking Methodology. The team interviewed various patients and their caretakers to establish their needs and to fully understand the design requirements. Once these interviews were completed, the team could establish a list of needs and possible solutions to these problems.

The team’s first idea, a hand-held device to open jars, was found to be already mass produced on the market. Therefore, the team decided to execute the second design option, which was a product that would help people with mobility problems to sit and/or stand up, decreasing the chance that a caretaker would sustain injuries while doing so. Although similar products are on the market, they are expensive and may require electronic assistance and/or require the patient to possess great upper body strength. This design is different because it allows the user to sit or stand without exerting too much upper body strength, while being cost effective enough to be available to patients of diverse financial status.

In total, three different prototypes were created. Each prototype varied in design aspects such as ergonomics, force distribution, cost effectiveness and possibility to manufacture. The final design took the constructive inputs and positive features of prototypes I and II into consideration. The product analysis consisted of free-body diagram evaluations, SolidWorks CAD, Autodesk Fusion 360 Finite Element Analysis and biomedical evaluations to ensure the safe handling of users. In addition, today’s market was evaluated to ascertain how marketable and profitable the product could be. The product was found to be competitive on the market. It also met the requirements established for the success of the project.

This project was supported by the National Science Foundation contract CBET-1403753, “Making the Difference: An Industrial Engineering Capstone Design Experience to Benefit Adults with Disabilities.”